| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Brand Name : chuangying

Place of Origin : dongguan

MOQ : 1 set

Price : $7800.00/Sets 1-4 Sets

Dimensions : 3800(L)×980(W)×1100(H)mm

Adaptable material : non-woven fabric (9-10g/m2) Rubber band model (30-40 yarn wrapping)

Rated voltage : 220V±5%

Rated power : 3Kw

High speed bouffant cap making machine plastic PE cap disposable hat making machine

Bar Cap Making Machine Instructions

The company independently developed "non-woven bar cap", which is the first manufacturer of elastic non-woven head cover.

Special machinery, the products are suitable for hospitals or dust-free industries, etc. The machine is stainless steel structure, independent

The electrical control box only needs one person to operate, from feeding to forming, counting and collecting to complete automatic control.

The system can produce up to 200 pieces per minute.

◆ High stability, excellent performance and low failure rate

◆ Stainless steel structure, independent electrical control box, compact machine, small rest volume

◆ The surface parts are all chrome-plated, and the cover parts are made of stainless steel, which is beautiful and clean

◆ Adjustable ultrasonic welding

◆ One machine is changeable, changing molds can produce bar caps of various specifications

◆ Electronic counting

◆ Automatic shutdown protection for broken material / broken ribs

| Specifications of bar caps produced | 18′-24′ single rib/double rib |

| Production speed | According to the thickness of the material, the best control is 90-120p/m (the machine life can be lasting, more than 150 will damage the mold). |

| Weight of the whole machine | 450KG |

| Adaptable material | non-woven fabric (9-10g/m2) Rubber band model (30-40 yarn wrapping) |

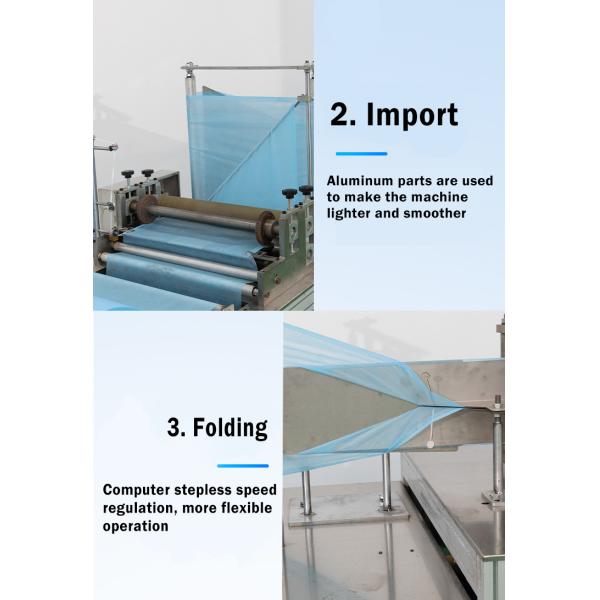

Look below, the elastic band is loosened and the plastic film is shrunk (it should have a regular pattern of folds, but it's broken here...).

Probably imagine the kind of elastic pants for children. First stretch the elastic band and evenly sew it on the waistband. Then, when the elastic band is loosened, the waistband shrinks to form small pleats. When wearing, pull the waistband of the trousers open, you can wear it...

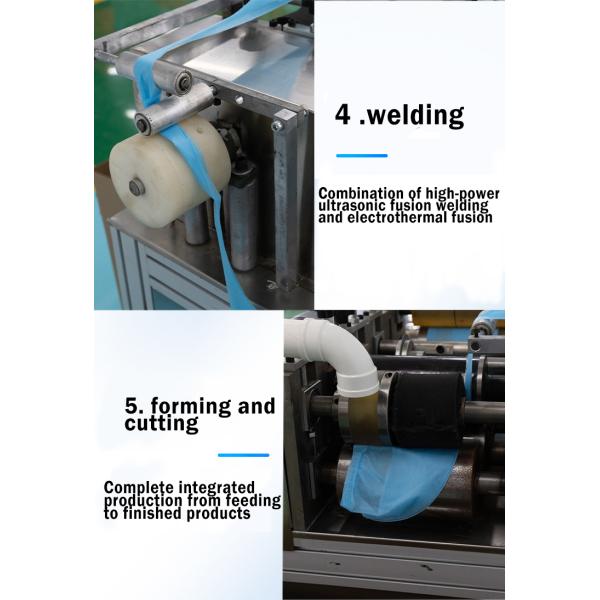

Welding and forming

The folded material will continue to pass through the transverse ultrasonic welding wheel and be welded at certain intervals. See the wheel with a small tail in the middle of the picture below. This is to control the circumference, which is about the length of a shower cap. Such a weld is the common weld of the brim of the two hats. Turn 2 into ∞ , and then cut it into o o , and it becomes a ring that can be worn on the head.

|

|

Digital Intelligence Bouffant Cap Manufacturing Machine Adjustable Ultrasonic Welding Images |